1100 Gamma-Ray Source Projector.

Lightweight, longer service life, and safer, simple operation

Radiographers use the 1100 Gamma-Ray Source Projector to perform industrial gamma radiography using Ir-192 and Se-75 on welds, castings, and structural components.

As QSA Global's newest gamma-ray source projector, the 1100 is safer, easier to operate, and lasts twice as long as the 880 Series Delta. A new ergonomic handle makes the projector more comfortable to carry, and a larger label area supports required IATA transport markings, eliminating the need for overpack labels. Backward compatibility with 880 Series controls, guide tubes, and shielding allows NDT service providers to upgrade without retraining crews or replacing existing equipment.

QSA Global designed, tested, and manufactured the 1100 Gamma-Ray Source Projector to meet ANSI N432-1980, ISO 3999:2004(E), IAEA SSR-6 (2012 & 2018), USNRC 10CFR34, 10CFR71, and 49CFR173 to ensure safe, compliant operations in field environments.

1100 Features for Safer, Simpler Operation

-

![1100 Field Replaceable Lock Operate]()

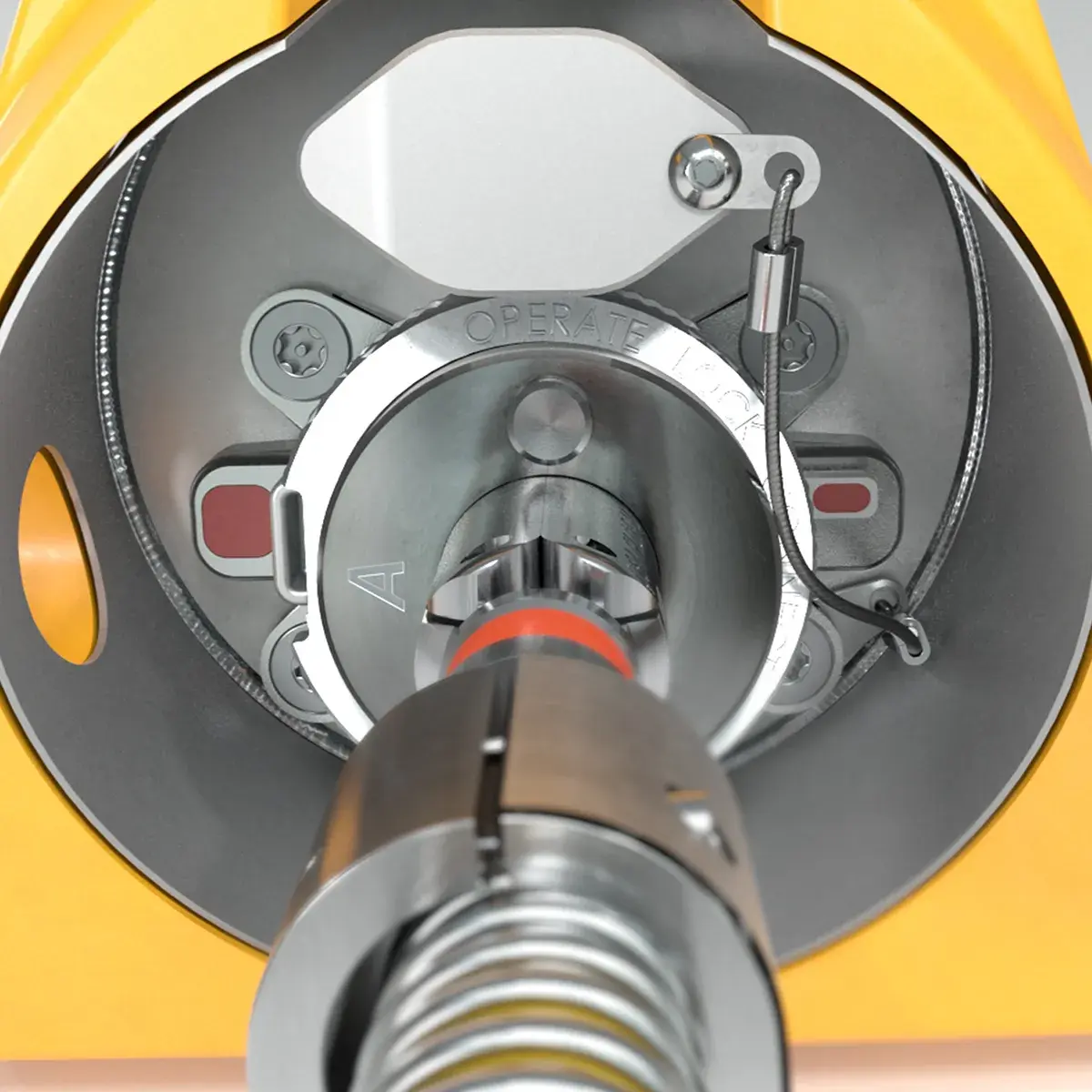

Avoid Downtime from Lock Failures

The new lock has a field-replaceable core that RSOs can swap out on-site, keeping the 1100 in service and inspections on schedule. A larger lock slide with improved position identification and side access helps radiographers confirm lock status and shutter position at a glance. -

![1100 Front Plate Indicators]()

Make Confident Connections

Color-coded CONNECT, SECURE, and OPERATE front plate indicators guide radiographers through guide tube connection. Better side access at the rear plate and improved lock slide visibility confirm that the source is securely locked and safe before exposure, reducing misconnect risk and operator dose. -

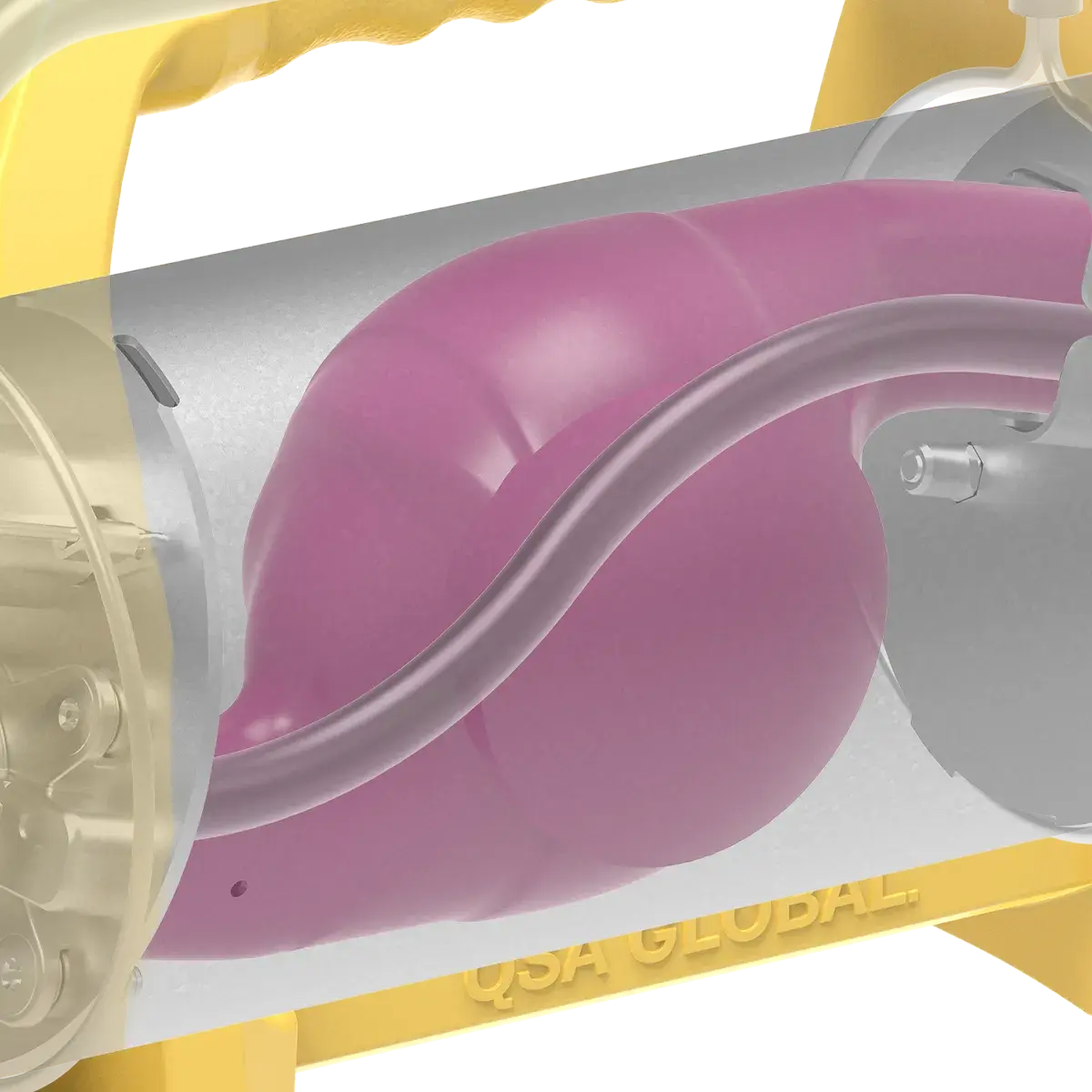

![1100 S-Tube Ilustration]()

Get Twice the Service Life

Get twice the service life with a new S-tube design with improved, thicker tubing, and optimized geometry. The 1100 includes a 3-year S-tube warranty to help you avoid unplanned capital expenses and workflow delays from premature replacement. -

![Side view of the gold 1100 gamma ray source projector]()

Enjoy Lighter Weight

Weighing 48 lb (22 kg) with the jacket, the 1100 is under the 50 lb limit for one‑person handling. Radiographers can carry and position the projector themselves, reducing the need for added crew members and improving access to confined spaces.

Specifications: 1100 vs. 880 Delta

| Specification | 1100 | 880 Series Delta | Notes |

|---|---|---|---|

| Weight (with jacket) | 48 lb (22 kg) | 55 lb (25 kg) | 7 lb (3.2 kg) lighter and safe for one-person operation. |

| Max Source Activity | Ir-192 (Model A426-1): 150 Ci (5.55 TBq) Se-75 (Model A426-2): 150 Ci (5.55 TBq) |

Ir-192: 150 Ci (5.55 TBq) Se-75: 150 Ci (5.55 TBq) Yb-169: 108 Ci (4.00 TBq) |

Same max source activity for Ir-192 and Se-75. Yb-169 only available on the 880 Series Delta |

| Labeling Area | 8.25 × 10.52 in (20.96 × 26.72 cm) |

6.13 × 9.50 in (15.57 × 24.13 cm) |

Larger area on the 1100 supports IATA marks without overpack labels |

| S-tube Warranty | 3 Years | 1 Year | 1100 tested internally for 2x ISO3999 Standards (100k Cycles) |

| Lock Assembly | Small Format Interchangeable Core (SFIC) lock with a replaceable core | Vertical Lock Assembly | 1100 field-replaceable core that RSOs can swap out on-site |

| Transport Package | Type B(U) Certified Package | Type B(U) Certified Package | Same transport package |

Accessories

The 1100 gamma-ray source projector is approved for use only with authorized QSA Global sealed sources and accessories. All accessories are interchangeable across the 880 Series, SENTRY, and 1075 SCARPro models, making it easy to upgrade your devices, standardize your fleet, and simplify field operations.

Support That Shows Up in the Field

-

Daily Gamma Radiography Equipment Inspection: A Step-by-Step Guide

Daily equipment inspection is a crucial safety requirement before performing gamma radiography. Both Agreement State and NRC regulations mandate ...

-

How to Perform a Misconnect Test: Safety Procedure for RSOs

The 30-second misconnect test is a mandatory safety procedure, required by radiation safety regulations, that verifies if your radiography ...

-

How to Perform a Leak Test on Your Gamma-Ray Source Projector

Performing a leak test on your gamma radiography projector is a required part of maintaining compliance with NRC and Agreement State regulations. ...

-

How to Perform a Radiation Survey on a Loaded Gamma Projector

If you’re handling a gamma projector, be it coming in through your transport or coming off the rig onto the job site, the first thing you should ...

-

How to Inspect Drive Cables: A Field-Ready Guide for NDT Techs

Drive cables take a beating. Between setup, teardown, transport, and exposure to rough site conditions, they're one of the first components to ...

-

How to Inspect Guide Tubes: A Field-Ready Guide for NDT Techs

Routine inspection of guide tubes and collimators helps prevent source retrievals and ensures equipment remains safe and functional. The steps ...

-

How to Inspect Projector Components for Safety and Compliance

A crucial part of your role as a radiographer is to ensure your equipment functions safely and remains in compliance with certification ...

Order the 1100.

Are you ready to configure the 1100 gamma-ray source projector? We'll help you select the right isotopes, focal sizes, and accessories for your gamma radiography applications and compliance requirements.