OpenVision HD Real-Time Radiography X-Ray System.

Protect asset value with fast, data-driven CUI screening and crystal-clear visual insights.

OpenVision HD is a handheld real-time radiography (RTR) X-ray system used for qualitative CUI screening on insulated piping. It provides live high-definition video and still images that reveal CUI indicators such as pitting, scaling, external wall loss, and wet insulation as small as 0.010 inch (250 μm) without removing insulation or disrupting revenue-generating operations.

OpenVision HD's superior CMOS imaging delivers crystal-clear visual insights that make early-stage corrosion easier to detect and prioritize. Radiographers can screen hundreds of feet per shift at 30 seconds per foot (0.30 m), while low-energy X-rays allow daytime screening without disrupting production. These capabilities support faster, more targeted CUI screening that maximizes asset coverage within budget constraints, making OpenVision HD ideal for risk-based inspection programs.

OpenVision HD follows ANSI/HPS N43.5 (2005), ISTA 3A, MIL-STD-810 Method 514 Annex C Category 4, and REACH/ROHS requirements.

New Features to Maximize Your Probability of Detection

-

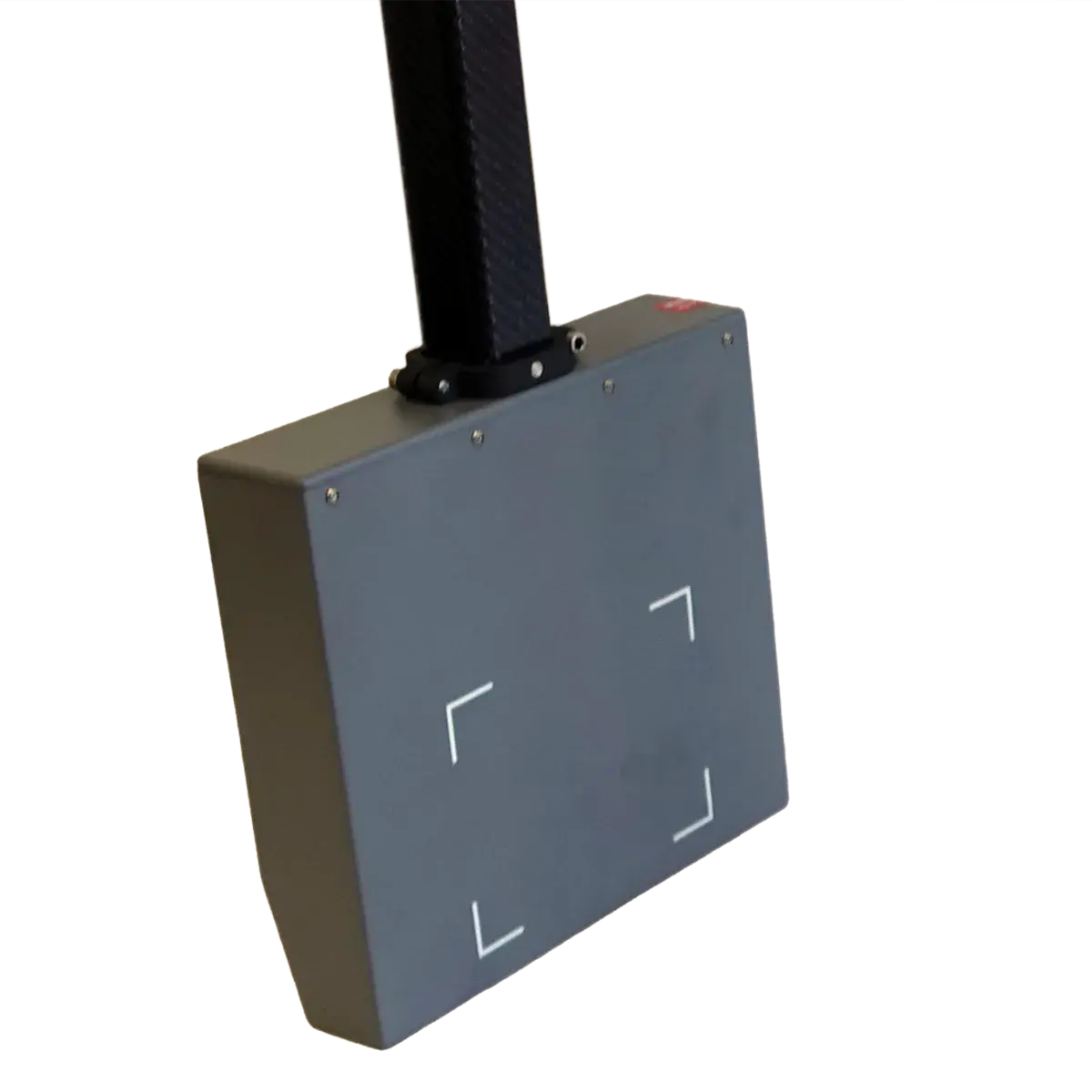

![OpenVision HD CMOS Detector]()

ACCURATELY DETECT CUI

New CMOS imager generates high-contrast, high-definition videos and images. It shows CUI indicators as small as 0.010 inch (250 μm) to help you prioritize maintenance, plan repairs, and avoid unnecessary insulation removal.

-

![OpenVision HD Handles]()

CAPTURE CUI WITH EASE

New handles with multiple mounting points on the C-arm and an integrated trigger enhance ergonomics, reduce fatigue, and simplify operation. This helps you maintain consistent screening performance during long shifts and complex jobs.

-

![OpenVision HD Folding C-arm]()

MINIMIZE DOWNTIME

The new folding C-arm protects against impact when navigating scaffolding, rope access, or tight piping runs. It folds down for safer transport and easier handling, preventing equipment damage and extending service life.

-

![OpenVisoin HD Extended C-arm]()

REACH MORE PIPING

The new extendable detector arm improves access to complex or obstructed piping configurations. Crews can screen faster and reach piping sections typically missed, without stopping to reposition the system.

OpenVision HD Specifications

| Imaging Technology | Digital CMOS detector |

| X-ray Source | Integrated 70 kV X-ray tube |

| X-ray Output at 12 in (30.5 cm) | Low: 40 kV, 0.300 mA, 50 R/hr (0.5 Sv/hr) Medium: 55 kV, 0.218 mA, 80 R/hr (0.8 Sv/hr) High: 70 kV, 0.171 mA, 95 R/hr (0.95 Sv/hr) |

| Pixel Pitch | 74.8 μm |

| Active Imaging Area | 5.72 × 4.52 in (145.4 × 114.9 mm) |

| Grayscale Depth | 16-bit |

| Capture Modes | Real-time video, still images, and target images |

| Still Image Resolution | 1944 × 1536 px |

| Captured Video Resolution | 1280 × 720 px |

| Storage Capacity | Internal: 128 GB WiFi Tablet: 128 GB |

| Export Options | USB file transfer |

| Construction Materials | Aircraft-grade aluminum housings and stainless steel reinforced joints |

| C-arm Weight | 16 lb (7.2 kg) |

| Wired Monitor Weight | 2 lb (0.9 kg) |

| Shipping Weight | 50 lb (23 kg) |

| Startup Time | ~30 seconds |

| Shutdown Time | ~5 seconds |

| Battery Life (5 Ah) | 2 hours continuous, 3 hours standby |

| Operating Temperature | -20 to 120 °F (-29 to 49 °C) |

| Storage Temperature | -20 to 140 °F (-29 to 60 °C) |

OpenVision Accessories

OpenVision accessories work together as an integrated unit to support high-speed qualitative screening in complex insulated piping systems. These accessories help CUI inspection teams minimize fatigue, maintain data quality, and reduce inspection time.

OpenVision HD FAQs

-

What is real-time radiography?

Real-time radiography (RTR) is an advanced, non-destructive testing method that provides live visualization of the internal structures of a component or system without disassembly or destruction.

OpenVision is a type of RTR that uses high-definition imaging technology to provide clear, detailed videos and images of corrosion, flaking scale, pitting, external wall loss, and wet insulation in real-time. This immediate, accurate visual feedback enables inspectors and asset integrity managers to make informed decisions on the spot about the condition of their assets, significantly improving maintenance efficiency and safety.

Whether for routine CUI inspections or rapid diagnostics in response to an issue, OpenVision HD's real-time radiography capabilities serve as a crucial tool in maintaining the health and integrity of critical assets.

-

Are there specific insulation types or materials that OpenVision HD is especially effective or ineffective with?

OpenVision HD performs best on insulated piping systems with aluminum or stainless steel cladding and insulation materials like perlite, calcium silicate, cryogel, foam glass, or mineral wool. Performance depends on factors such as outer diameter, insulation thickness, and cladding gauge.

View our Application Matrix to see which configurations are best suited for screening.

-

What is the smallest CUI defect I can see with OpenVision HD?

With OpenVision HD, you can view external defects as small as 0.010 inches (250 microns) on insulated piping.

-

How should I grade OpenVision HD data?

We recommend grading OpenVision data like you would a visual inspection. Here’s an easy classification roadmap you can adapt to your reporting process:

🟢 Green: No CUI present. No additional action is required.

🟡 Yellow: Minor CUI present. Consider a quantitative inspection.

🟠Orange: Moderate CUI present (e.g., scaling). Quantitative inspection and/or insulation removal is necessary.

🔴Red: Critical CUI present (e.g., only insulation is holding the piping together). Rectification Required.

We recommend including both the screen captures from OpenVision HD and your visual observations of the piping in your reports.

View an example of what you might see on the OpenVision HD screen and how you could grade it in report here: How to grade OpenVision HD data.

-

How fast can OpenVision HD screen a standard section of insulated piping?

Radiographers screen insulated piping at a rate of 30 seconds per foot (0.30 m) using OpenVision HD. Actual screening speed depends on the radiographer, piping configuration, and number of CUI indicators found during inspection.

When radiographers detect CUI indicators on the real-time video, they capture still and targeting images for follow-up.. Overall, radiographers complete CUI screening up to 60 times faster using OpenVision HD than with traditional screening methods. -

What safety features are built into OpenVision HD to protect operators and nearby workers?

OpenVision HD utilizes a highly collimated X-ray beam to direct X-rays toward the object being screened and away from the operator.

Warning lights, a warning screen, and an audible ensure the operator is aware before X-rays are generated and during operation. A trigger interlock ensures the X-ray tube is not accidentally activated.

-

How long does it take to set up and break down OpenVision HD on a job site?

You can set up and start using OpenVision HD within 1-2 minutes. In most cases, no exclusion zone is required to operate OpenVision HD, so breakdown takes seconds. If a country's regulation requires an exclusion zone, it's so small that breakdown is still very quick.

-

What are the overall transport and storage dimensions of OpenVision HD?

OpenVision HD and its accessories are stored and transported in a customized Pelican™ case with external dimensions: 32 in x 20.5 in x 12.5 in (82 cm x 52 cm x 32 cm).

-

What training do you offer?

QSA Global, Inc. offers a two-day course at our OpenVision Learning Centers in La Porte, TX and Pilsen, Czech Republic. The course includes a combination of classroom and hands-on practical sessions. An expert in industrial radiography, approved by QSA Global, Inc.'s Radiation Protection & General Safety Committee (RPGSC), provides the training for this course.

Upon successfully completing the written and practical exams, students will receive a training certificate confirming their proficiency.

Support That Shows Up in the Field

-

Case Study: How BP Uses OpenVision in Their 4-Step CUI Management Program

With over 30 years’ experience in the development, implementation, and management of pipeline and pressure systems integrity management programs, ...

-

Using Real-Time Radiography in CUI Inspection Programs

Corrosion Under Insulation (CUI) remains a persistent and expensive challenge in the process piping industry. In refineries, petrochemical plants, ...

-

Advancing CUI Detection: The Shift to Risk-Based Inspection

For oil and gas, power generation, and petrochemical facilities, Corrosion Under Insulation (CUI) remains one of the most costly and difficult ...

-

Rethinking CUI Management: A Costly and Reactive Approach

Corrosion Under Insulation (CUI) remains one of the most expensive and unpredictable challenges asset owners face, with industry estimates ...

Experience OpenVision HD.

See OpenVision HD in action. Our field experts will walk you through a live OpenVision demo and help you choose the right system and accessories for your CUI inspection needs.